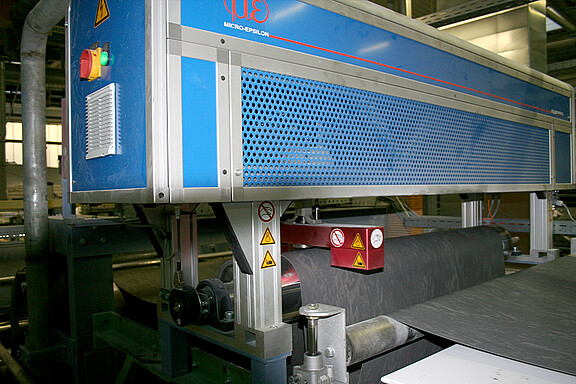

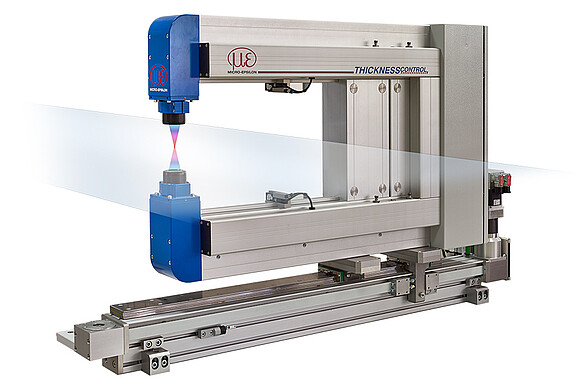

Production et transformation des matières plastiques

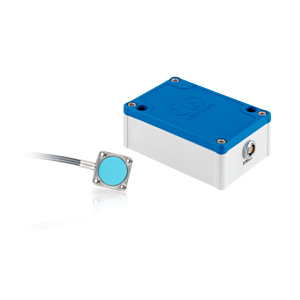

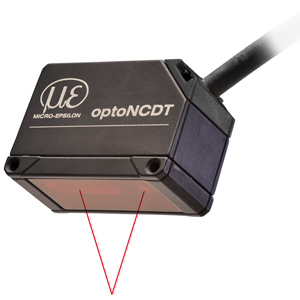

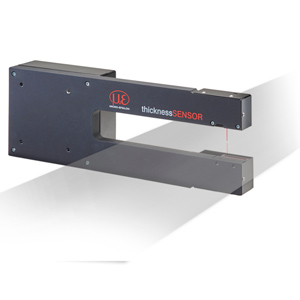

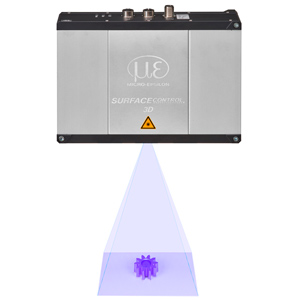

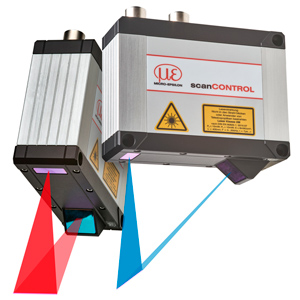

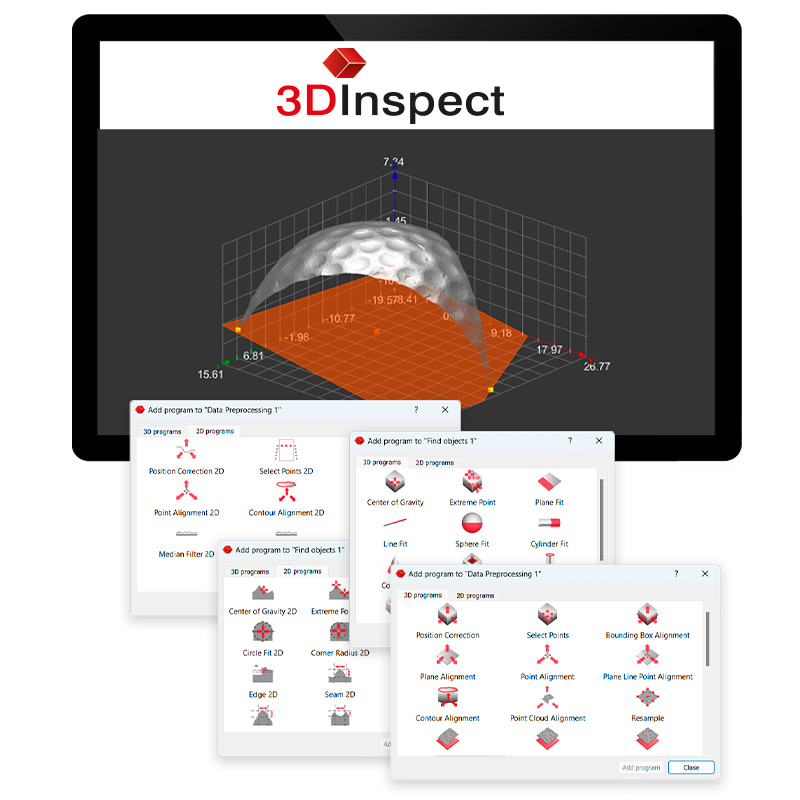

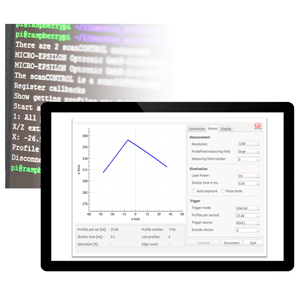

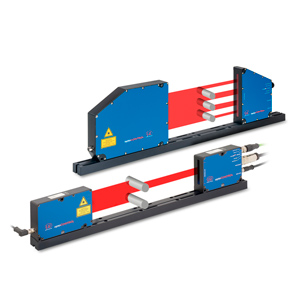

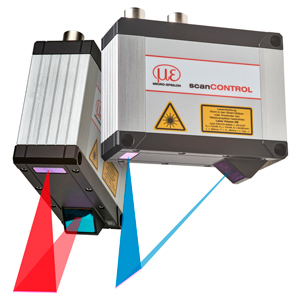

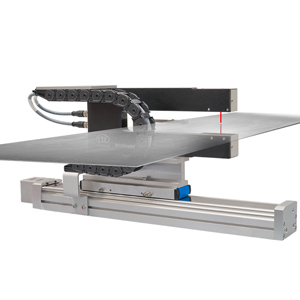

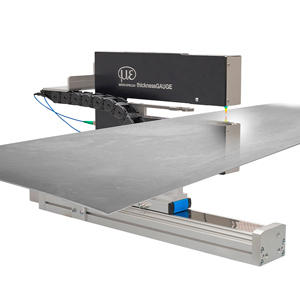

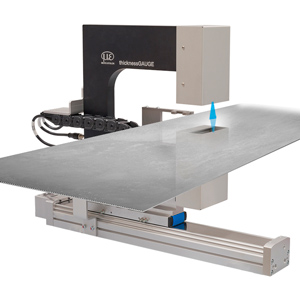

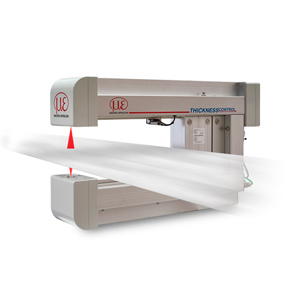

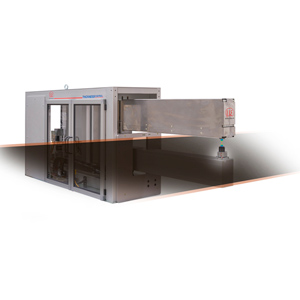

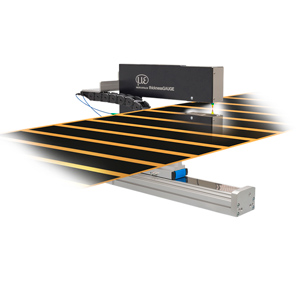

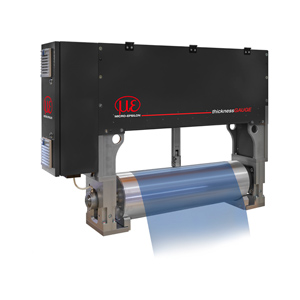

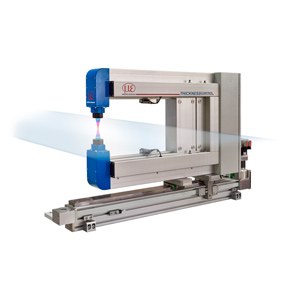

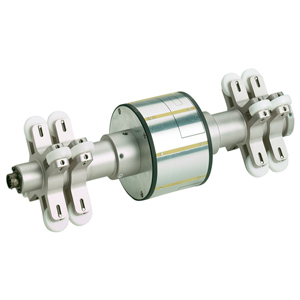

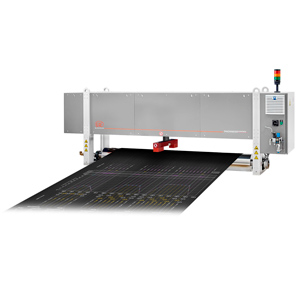

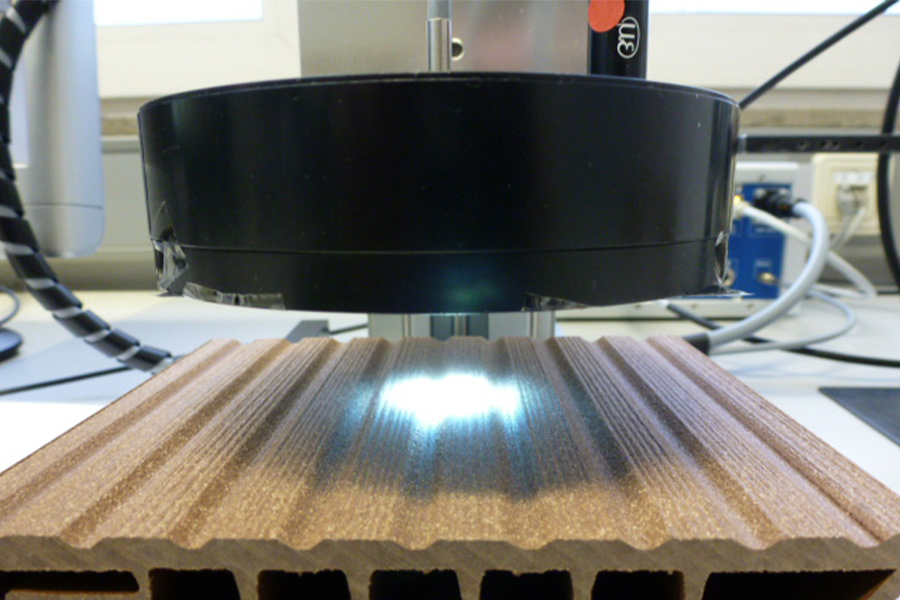

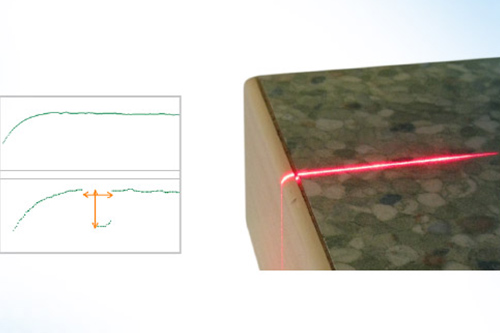

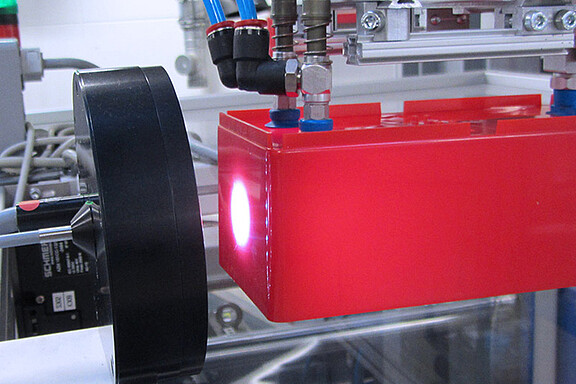

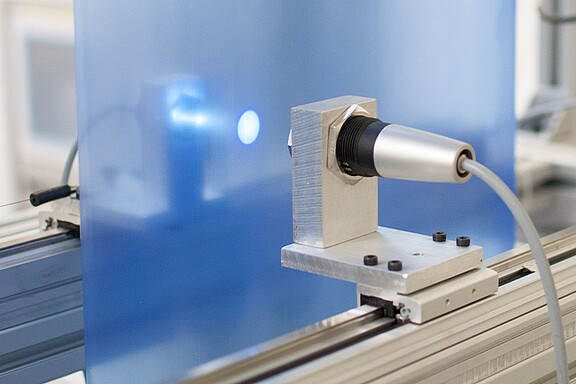

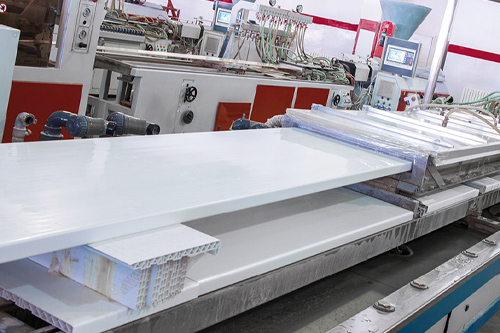

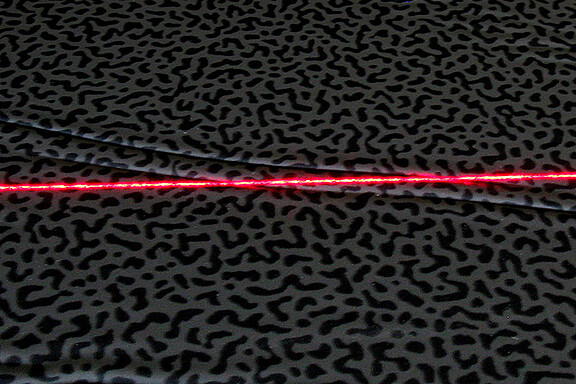

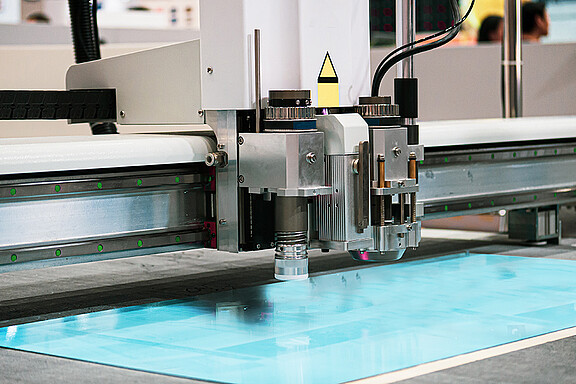

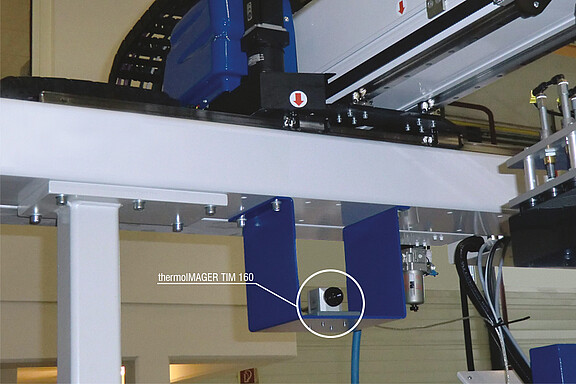

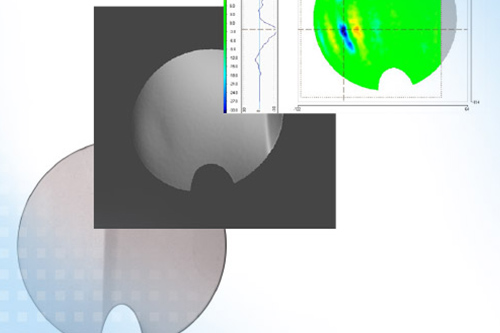

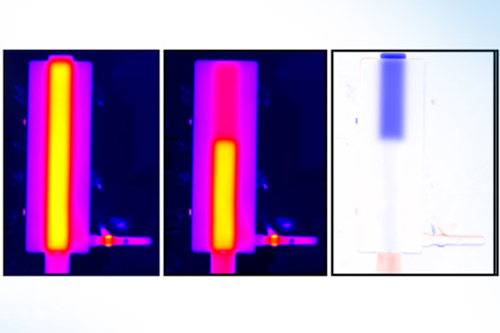

Micro-Epsilon propose une large gamme de capteurs et de solutions pour la mesure sans contact dans la production de matières plastiques. Les grandeurs telles que les dimensions, l'épaisseur, la température, les couleurs et les motifs de gaufrage sous forme de rouleau ou de feuille sont mesurées de manière fiable dans une grande variété d'étapes du processus - de l'extrusion au traitement ultérieur en passant par le formage.